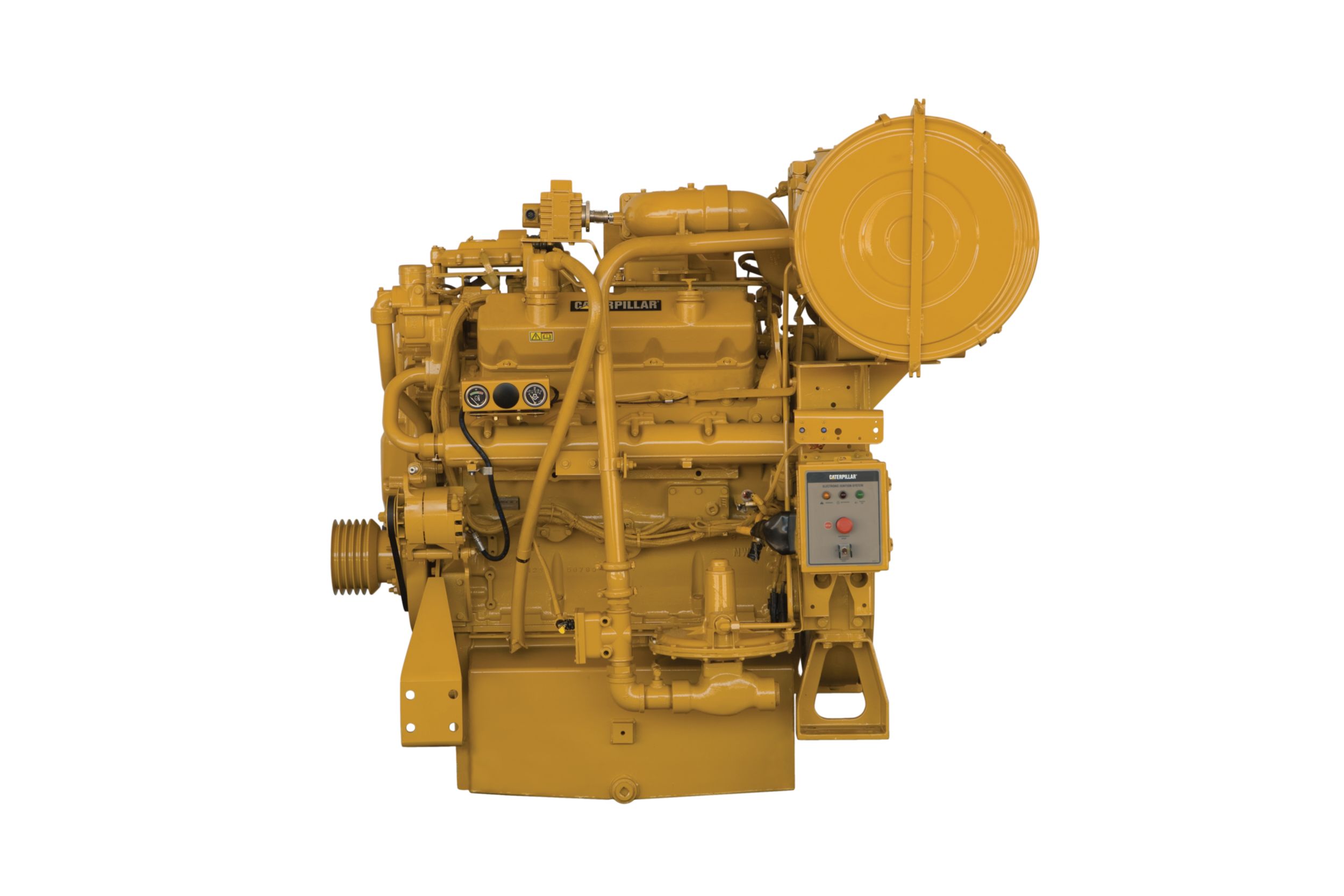

Cat G3408C

Lang holdbarhed i de mest barske miljøer er kendetegnende for G3400-platformen, hvilket sikrer maksimal oppetid og lave driftsomkostninger. G3408C-motorer er konstrueret til kontinuerlig drift og har i praksis vist, at de stort set ikke har uplanlagt nedetid. Denne motor anvendes bl.a. til gasløft, gasopsamling og kompression ved brøndhovedet. Cat G3408C gas-kompressionsmotorer er klassificeret til 317 bkW ved 1.800 omdr./min. og er NSPS-kompatible - men kan naturligvis også anvendes i ikke-regulerede markeder. Som bruger kan du selv angive den ønskede efterbehandling.

Specifikationer

Engine Specifications

| Maximum Rating | 317 bkW |

| Emissions | NSPS Site Compliant Capable or Non-regulated |

| Displacement | 18 l |

| Minimum Rating | 317 bkW |

| Compression Ratio | 8.5:1 |

| Aspiration | Turbocharged-Aftercooled |

| Rotation from Flywheel End | Counterclockwise |

| Flywheel and Flywheel Housing | SAE No. 0 |

| Flywheel Teeth | 136 |

| Weight - Dry | 2245 kg |

| Oil Change Interval | 750 hours |

| Ignition, Protection | Cat EIS |

| Stroke | 152 mm |

| Bore | 137 mm |

Capacity for Liquids

| Cooling System | 54.9 l |

| Lube Oil System - Refill | 147.63 l |

Cat Engines For Gas Compression

Download (PDF)Fordele og funktioner

Engine design

• Improved reliability and durability • Ability to burn a wide spectrum of gaseous fuels • Robust diesel strength design prolongs life and lowers owning and operating costs• Broad operating speed range

Emissions

Meets U.S. EPA Spark Ignited Stationary NSPS Emissions for 2007/08

Lean burn engine technology

Lean-burn engines operate with large amounts of excess air. The excess air absorbs heat during combustion reducing the combustion temperature and pressure, greatly reducing levels of NOx. Leanburn design also provides longer component life and excellent fuel consumption.

Cat® electronic ignition system (eis)

Detonation sensitive timing protects the engine against detonation damage. Higher voltage and longer spark duration mean easier starts, fewer misfires, and smoother operation. Diagnostic codes help pinpoint cylinder and component of interest. Spark plug maintenance codes identify spark plug condition

Ease of operation

• Deep sump oil pan has a larger capacity for normal 750-hour oil change intervals• Side covers on block allow for inspection of internal components

Full range of attachments

Large variety of factory-installed engine attachments reduces packaging time

Testing

Every engine is full-load tested to ensure proper engine performance.

Gas engine rating pro

GERP is a web-based program designed to provide site performance capabilities for Cat natural gas engines for the gas compression industry. GERP provides engine data for your site's altitude, ambient temperature, fuel, engine coolant heat rejection, performance data, installation drawings, spec sheets, and pump curves.

Product support offered through global cat dealer

More than 2,200 dealer outletsCaterpillar factory-trained dealer technicians service every aspect of your petroleum engineCat parts and labor warrantyPreventive maintenance agreements available for repair-before-failure optionsS•O•SSM program matches your oil and coolant samples against Caterpillar set standards to determine:- Internal engine component condition- Presence of unwanted fluids- Presence of combustion by-products- Site-specific oil change interval

Over 80 years of engine manufacturing experience

Over 60 years of natural gas engine productionOwnership of these manufacturing processes enables Caterpillar to produce high quality, dependable products.- Cast engine blocks, heads, cylinder liners, and flywheel housings- Machine critical components- Assemble complete engine

Web site

For all your petroleum power requirements, visit www.catoilandgasinfo.com